-

-

ProductsProductsTweezers TweezersCutters and Pliers Cutters and PliersScissors ScissorsProbes and Spatulas Probes and SpatulasScalpels and Blades Scalpels and BladesWorkbench Accessories Workbench AccessoriesTesters TestersVisual Inspection Visual InspectionKits KitsTweezersourView all

TweezersAll Tweezers High Precision Tweezers Cutting Tweezers Plastic Replaceable Tip Tweezers Biology Tweezers Diamond Tweezers Diamond coated Tweezers Plastic Tweezer Tips Plastic Tip Tweezers Full Plastic Tweezers Ceramic Replaceable Tip Tweezers Ceramic Tweezer Tips Full Ceramic Tweezers Mini Tweezers ESD Rubber Tweezers ESD Foam Tweezers ESD Diamond Coated Tweezers ESD Epoxy Coated Tweezers Cutters and pliersScissors and InstrumentsProbes and spatulasScalpels and bladesWorkbench accessoriesTestersVisual inspection

Cutters and pliersScissors and InstrumentsProbes and spatulasScalpels and bladesWorkbench accessoriesTestersVisual inspection -

Media

- Media

- News News

- Video

- Download

- FAQ and Insights

-

About Us

-

ContactsContacts

-

follow

us -

receive our

newsletter Register Now -

say

hello More

-

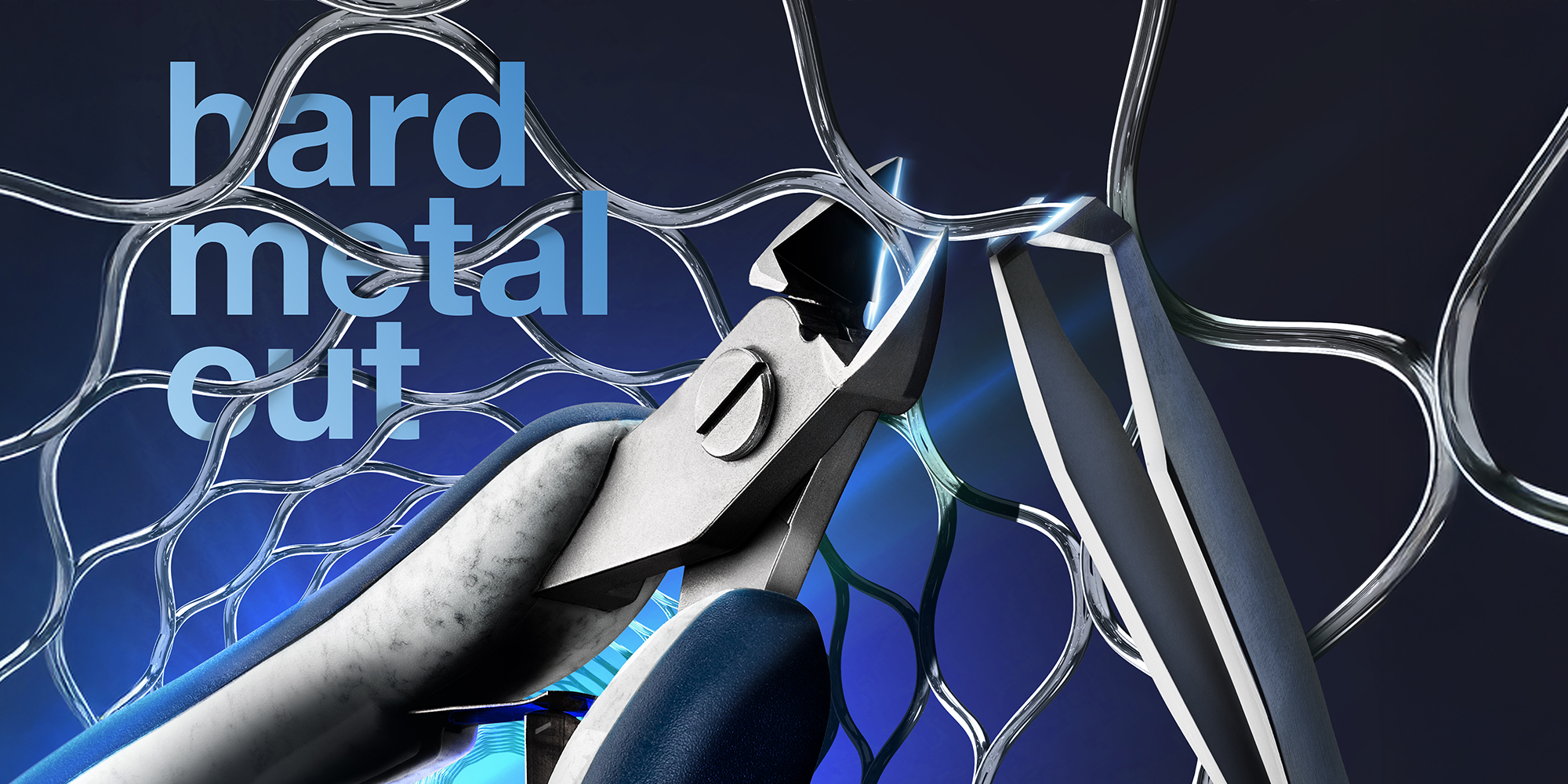

Hard metal cut

Hard metal cut. Cut the impossible.

On the production floor, some materials resist every attempt: nitinol, titanium, stainless steel, platinum. Stents that need trimming, braided mesh that won’t give way, catheters and guidewires that demand absolute accuracy.

That’s where Ideal-tek hard metal tools earn their place.

Built for single or multiple filars, quick stent trimming, and even lateral or internal “tip cuts” inside hardwire coils — they cut what lesser tools can’t. Their durability helps reduce faulty products and scraps, keeping productivity high and workers efficient shift after shift.

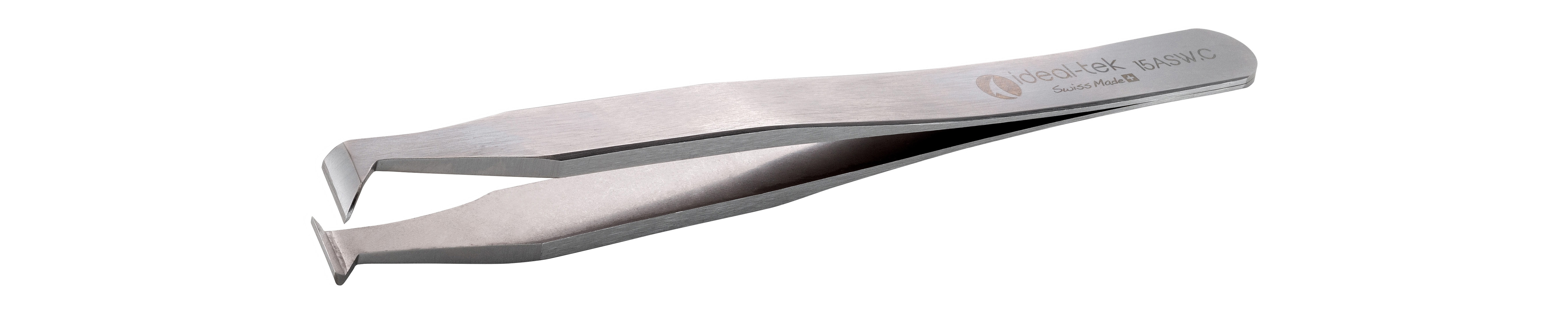

And when control meets resistance, our cutting tweezers bring the same reliability to delicate tasks in the most demanding medical device applications.

In medtech manufacturing, “impossible” is just another challenge to cut through.