-

-

ProductsProductsTweezers TweezersCutters and Pliers Cutters and PliersScissors ScissorsProbes and Spatulas Probes and SpatulasScalpels and Blades Scalpels and BladesWorkbench Accessories Workbench AccessoriesTesters TestersVisual Inspection Visual InspectionKits KitsTweezersourView all

TweezersAll Tweezers High Precision Tweezers Cutting Tweezers Plastic Replaceable Tip Tweezers Biology Tweezers Diamond Tweezers Diamond coated Tweezers Plastic Tweezer Tips Plastic Tip Tweezers Full Plastic Tweezers Ceramic Replaceable Tip Tweezers Ceramic Tweezer Tips Full Ceramic Tweezers Mini Tweezers ESD Rubber Tweezers ESD Foam Tweezers ESD Diamond Coated Tweezers ESD Epoxy Coated Tweezers Cutters and pliersScissors and InstrumentsProbes and spatulasScalpels and bladesWorkbench accessoriesTestersVisual inspection

Cutters and pliersScissors and InstrumentsProbes and spatulasScalpels and bladesWorkbench accessoriesTestersVisual inspection -

Media

- Media

- News News

- Video

- Download

- FAQ and Insights

-

About Us

-

ContactsContacts

-

follow

us -

receive our

newsletter Register Now -

say

hello More

-

ournewsletter

.png)

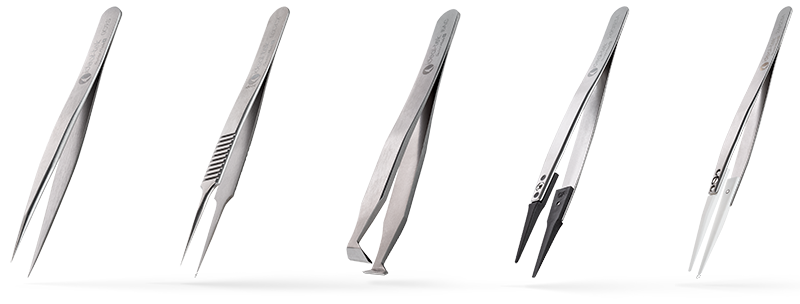

DG4 Full Diamond coated Cutting tweezers

High precision cutting tweezers with DG4 full tool length diamond coating provide the ultimate corrosion resistance and extended tool life, while maintaining their original cutting sharpness.

End users often hold cutting tweezers close to the tips where fingers can contribute to oxidation on the carbon steel cutting edges. DG4 coating delivers the highest level of corrosion resistance for carbon steel, making it perfect for the full body coating of cutting tweezers. The Diamond coating inhibits oxidation and resists wear and abrasion, ensuring reliable performance over time.

Watch ideal-tek training video

FEATURES

- Full blade coating

- 100% biological compatibility

- High wear and abrasion resistance

- Very low friction coefficient

- Excellent chemical resistance

BENEFITS

- Extreme corrosion resistance (RUST FREE)

- No metal contaminations or particle release

- Extended tool life

- Easy cutting

- Clean room compliant

- Easy to clean and maintain

The innovative plasma-assisted deposition technique used during the coating process ensures complete adherence to the material, making the tweezers completely biocompatible and free from any possible particle release or metal contamination. In addition, the tweezers become extremely resistant to wear and corrosion, making them perfect for demanding sectors such as medical device manufacturing biological and clean room environments. These tweezers are also perfect for precise applications including hearing aid, stent, pacemaker and other medical device manufacturing.

See more details on the product page and download the leaflet

6828 Balerna - Switzerland

Responsible person for EU

EU Authorized Representative

EU Authorized Representative For regulatory purposes only

Designated according to Regulation

(EU) 2023/988 - GPSR

22100 Como - Italy